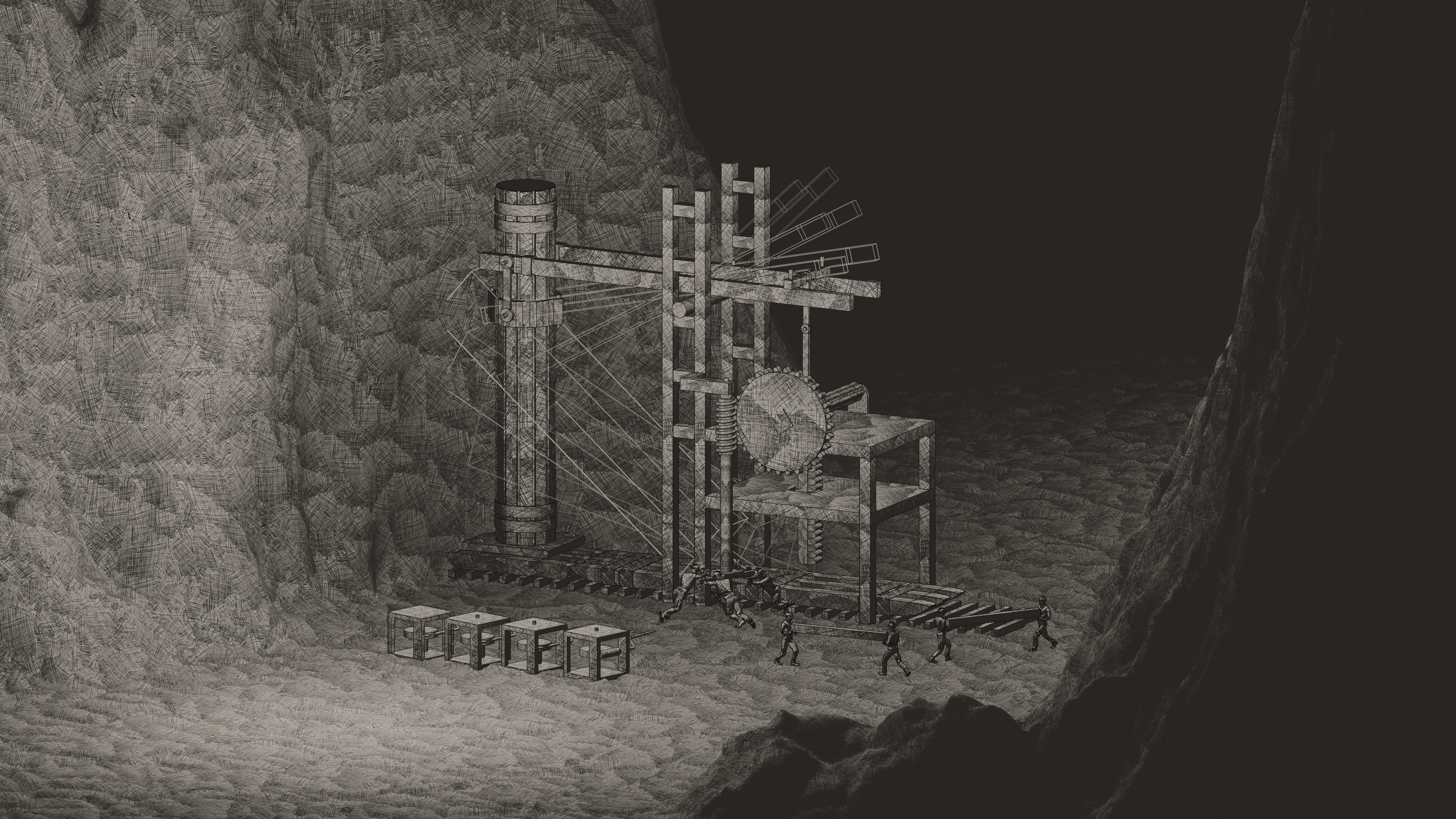

Vertical excavated shafts:

Lowering with a machine

Quarries exhibited significant diversity in their characteristics, including accessibility and stone hardness, varying greatly from one site to another. The Serevazza quarry, for example, posed significant challenges due to its remote location and treacherous terrain, necessitating Michelangelo's efforts to access the coveted marble. These natural disparities in quarries directly impacted the choice of machinery, as some machines required more space and were better suited for specific quarry conditions. To address these technical constraints, a novel approach is proposed. Unlike the previous method of "vertical excavated shafts: lowering with a pile of debris," which demanded substantial space, the new machine setup allowed for column lowering in confined areas, occupying just one column's length. This innovation streamlined the process, eliminating the need for two separate movements.

Machines depicted on folios 56R, 57R, and 57V in Francesco's Opusculum de architectura are adopted for this operation. These machines were selected for their unique arrangement, situating all components in front of the column to avoid mountain obstructions. Additionally, they enabled the column to be raised entirely off the ground, creating space for a sledge and cart beneath. Although these machines offered advantages, they had limitations, such as an inability to complete a full column rotation. To address this, a pile of debris supported the column's lowering once the machine reached its lowest point.

Animation

Francesco's devices were ingeniously designed to accommodate various column lengths, featuring a versatile ring-like connection. This adaptability proved advantageous compared to machines designed for specific column sizes. These innovations significantly improved the efficiency and adaptability of marble extraction, catering to diverse quarry conditions and column dimensions.